Digital Twin

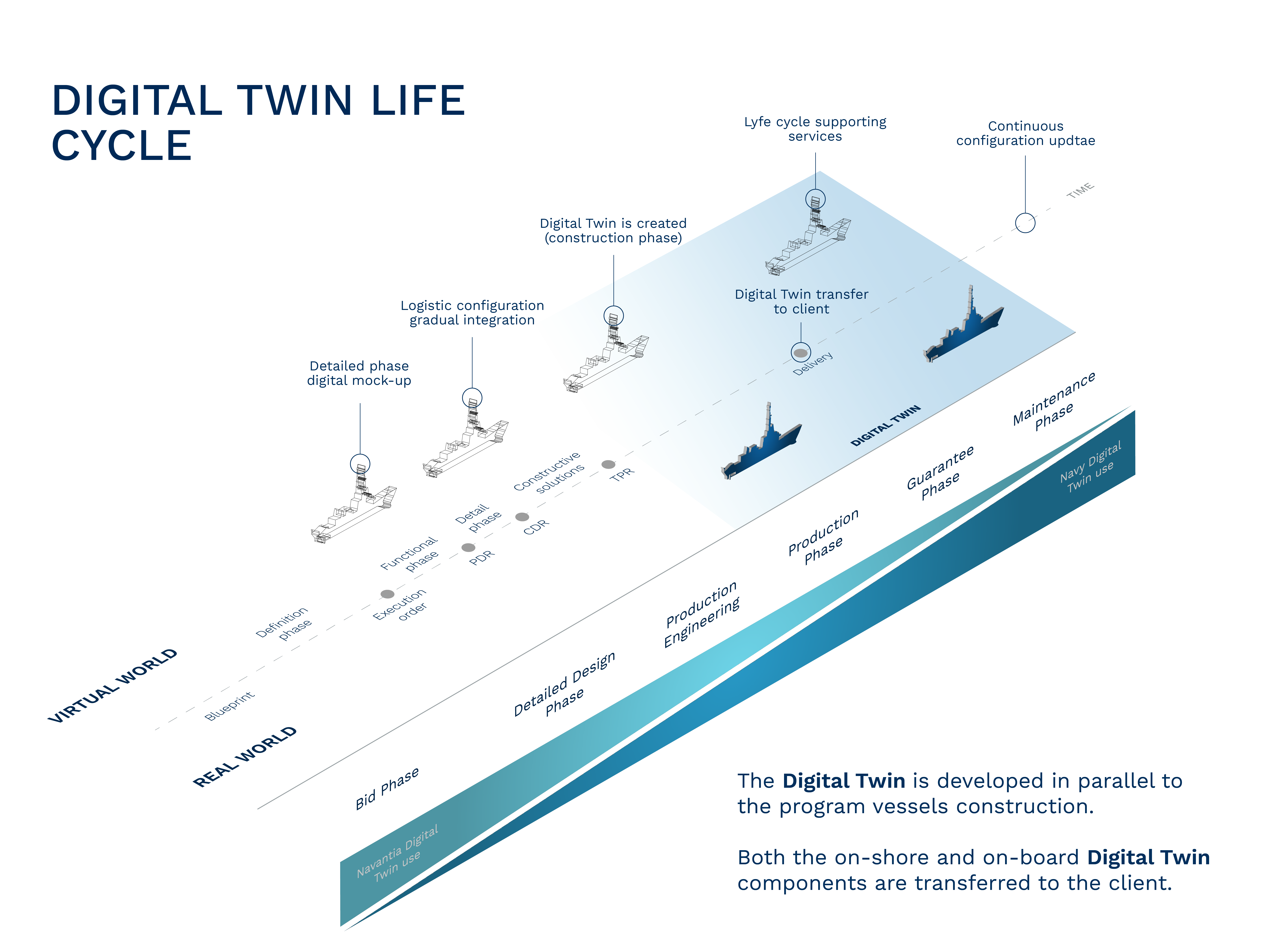

Digital Twin is a key concept for the Shipyard 4.0. It consists in a 3D virtual reality replica of a physical product. As the data feeds the Twin, it evolves to reflect how the physical product has been used and altered showing the environmental conditions to which it has been exposed. As an avatar of the real product, its Digital Twin allows the company to visualize the status and condition of the product thousands of miles away. The Digital Twin can also provide new insights and perspectives on the design, manufacturing, operation and services associated with the real Twin.

The Digital Twin allows to link the physical with the virtual environment of the product by applying technologies such as cloud computing, machine learning or IoT. In the virtual environment, data obtained during the whole life cycle is analyzed (from design to maintenance) to generate simulations which allow identifying corrective measures and recommend preventive actions.

Once the product is delivered, the virtual environment is delivered to the client, who will be able to exploit all the advantages it has to offer such as the simulation of operation scenarios, artificial intelligence (combat, malfunction diagnostics…), savings due to optimized maintenance…

The main advantages are:

- Optimize systems design or operation.

- Anticipate verification and validation processes.

- Real time tracking and response.

- Predictive maintenance, based on state and condition.

- Operation modeling and simulation of critical systems.

- Support for decision-making.

- Identify deficiencies when comparing the physical system with its digital models.

- Production planning based on real time situation instead of historic situation.

- Support staff with updated information.

- Services business models such as integrated software, advanced analytics application, data sales, asset management or operation support.

- Support to workers with updated information.