Project JOULES

The JOULES project (Joint Operation for Ultra Low Emission Shipping) has as main objective the reduction of greenhouse gases produced by the European maritime sector. This project is subsidized by the European Union under the 7th Framework Program and is coordinated by the German shipyard Flensburger Schiffbau-Gesellschaft. It started in June 2013 and during the last four years a consortium of 39 companies have been working with the common objective of finding systems for assessment and evaluation of the overall energy efficiency of the ship throughout its life cycle, from its construction to its scrapping.

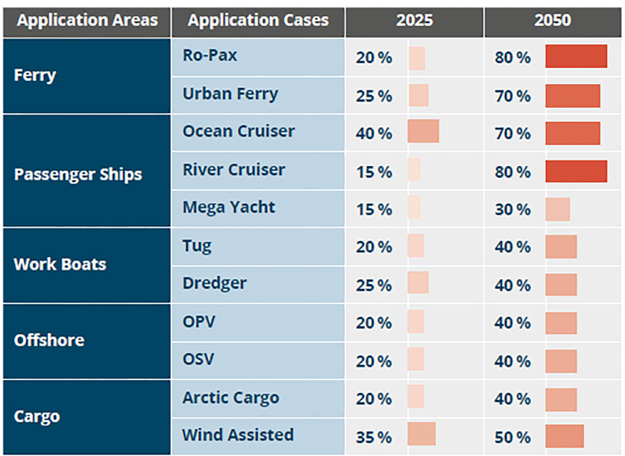

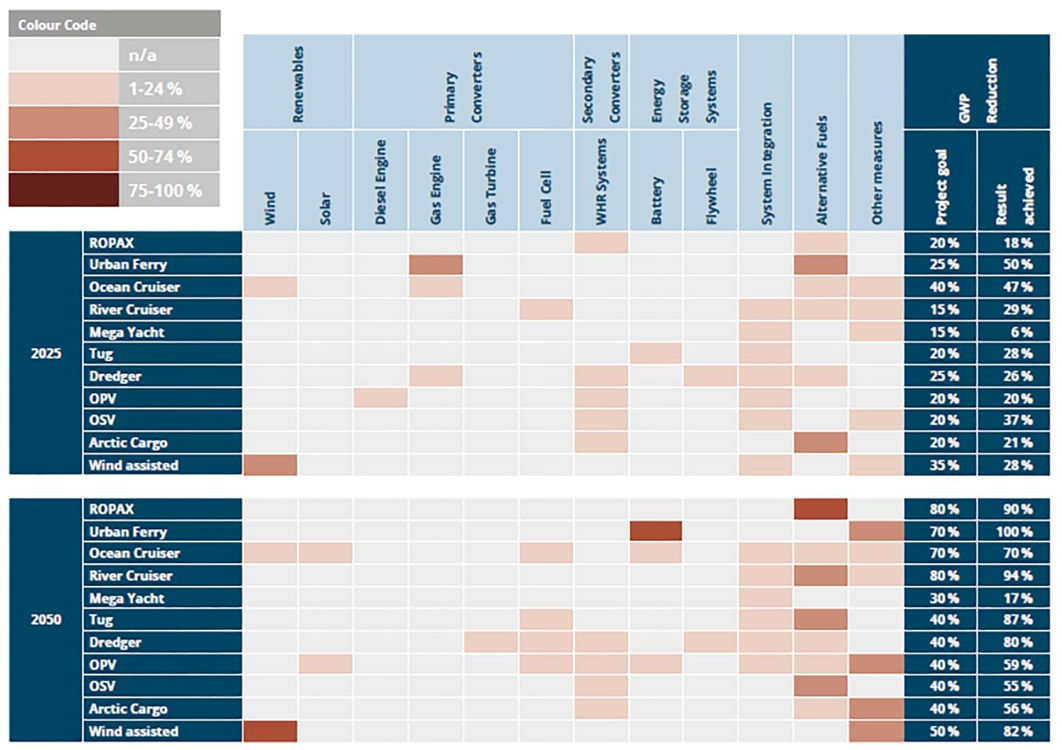

Objectives of reduction of maximum levels of greenhouse gases for each type of vessel.

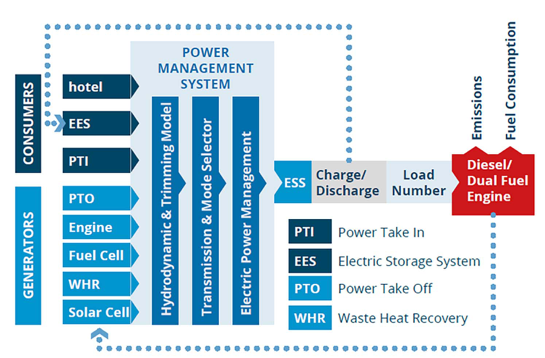

To achieve this objective, the main methodology used has been the development of energy component models of the ship through the integration of energy efficiency improvement technologies in a global energy management model of the ship that can be used from early conceptual definition stages and within a multidisciplinary advanced simulation environment.

In JOULES project, manufacturers and designers of technology, experts in simulation and models, and shipyards have joined our knowledge to develop innovative concepts of eleven cases of application that have been classified into 5 key areas: Passenger Ships, Cruises, Work Ships , Offshore Ships, Freighters. Each of these cases of application with a goal of reducing greenhouse gases, and in parallel other pollutant gases such as nitrogen oxides or sulfur.

To achieve the objectives of the project, initially the use of two basic tools was considered: the Simulation of the Global Energy Management Models (Energy Grid Model) of the ship and Life Cycle Performance Assessment Models. Finally, a complete methodology for evaluating technologies and systems aimed at improving the ship’s energy efficiency has been developed, consisting of:

- Web database of component models, developed by the equipment manufacturers according to the requirements of the project, and with an integration interface of Matlab simulation tools – Simulink, known as FMI (Functional Mock Up).

- Global Energy Models of the vessel, in order to assess and obtain the optimal energy configuration in the ship through the development of quasi-static or dynamic simulations.

- List of Fuels, where the physical and chemical properties of the different types of fuel are indicated, together with global environmental impact data from its manufacture to its use (“well to tank”), and forecasts of the price of fuel according to different social and political scenarios.

- Cycle of Life Behavior Cycle Models in which the following methodologies have been integrated:

Life Cycle Behavior Assessment to address environmental impacts through the use of KPIs.

Financial evaluation with Net Present Value (NPV) as KPI.

Economic and Environmental Integration. - Standardized interface for importing simulation results from the Energy Models of the Vessel to the “Life Cycle Performance Assessment” Model LCPA.

- Database where the emission factors for the Life Cycle Action Assessment are stored, and specific component costs.

In general, for the evaluation of improvements in energy efficiency, each application case has made three energy models of the vessel, corresponding three time and design scenarios: current baseline (reference design), expected design for 2020, and design 2050. The results of emissions of CO2, NOx, SOx, HC, PM and CH4, have been exported to the Life Cycle Behavior Model, for the assessment not only of the operation of the ship, but of other aspects such as emissions or energy cost during the production of fuels or materials that make up the ship, or economic aspects of manufacturing, operation and scrapping.

Database of components and technologies

Expert designers and manufacturers in each technology, including MAN Diesel & Turbo, Rolls Royce, Wartsila, or Saft, have developed the component models, receiving the support for the validation and verification of the models of European technological and research institutes such as Delft University or the University of Hamburg, and classification societies such as DNV-GL and Bureau Veritas. The full list of project participants can be found on the project website. (http://www.joules-project.eu/Joules/index.xhtml).

The component models are available in a database with web access for download by users for integration in the energy models and the realization of the corresponding simulations. Since the simulation tools used by the project participants are different, a model exchange tool known as “Functional Mock Up” has been selected, which allows the models to be used once they are translated and through input and output variables. on different platforms preserving intellectual and industrial property rights.

The validation and verification of the models is done in two phases. A first validation based on the component level, in which the actual performance data are compared with the models, and a final verification at the system level in which the demonstrators of certain selected systems will be performed.

Any new component that we want to install on the ship, requires a cost of construction, installation and operation. Through the assessment from the initial stages of the design of the vessel, estimates of energy consumption as well as consumption of materials can be obtained. Finally, there is a database of component models that allows the designer to integrate the models in their simulations, and obtain results and evaluations in a short time.

The technologies that have been studied can be classified into two fundamental groups:

- Technologies that reduce energy consumption

- Technologies that reduce polluting emissions

Emission reduction technologies

There are currently numerous studies of technological prospection that try to predict which solutions will be adopted within 20 or 40 years in the field of marine propulsion, and some of them try to take into account the influences of economic and socio-political factors that may deviate the tendencies towards some technologies or others. In the JOULES project, technologies to improve energy efficiency and reduce emissions have been classified into seven large groups covering energy production, consumer and post-treatment technologies.

- Primary energy converters

The primary energy converters are mainly responsible for propulsion and represent the most primary form of power generation of the ship. They are usually diesel engines that transform stored energy in the form of fuel into mechanical energy. Since they are the main producers of energy they are the main cause of polluting emissions. For this reason, designers of diesel engines have been forced in recent years by international and local regulations, to intensify their efforts in improving the environmental impact of these equipment. The result is reflected in the fact that current models offer better performance and lower emissions than their previous versions. In the field of fuels there have also been important advances aimed at the reduction of sulfur oxides, with fuels with a very low percentage of sulfur, or the use of natural gas, in what are known as dual engines that can consume liquid fuels and natural gas.

Other power production technologies that use fuels that are more respectful of the environment begin to have a relevant importance, such as gas turbines, gas engines, or fuel cells.

Regardless of the technologies currently available, the trend in the coming years will be greatly influenced by the evolution of fuel prices and the adaptation of alternative fuel supply infrastructures such as natural gas.

In the JOULES project, models of different types of primary converters have been developed, such as medium and high speed diesel engines, dual motors, gas engines, gas turbines, and fuel cells.

The project has focused on the optimization of primary converters, through intelligent control of these systems, and based on the improvement of energy distribution and management, taking advantage of the latest developments in electrical machines, electrical energy storage systems and the power electronics. On the other hand, in the simulations the influence of the use of different types of fuels has been evaluated, and the possibility of using after-treatment of the exhaust gases both for the cleaning of the gases and for the use of energy.

- Secondary energy converters

Secondary converters are all those equipment of the ship’s energy system that transform energy into a form that is usable for a certain function. The most common example are electric motors that transform electrical energy into mechanical, or systems for harnessing the energy of exhaust gases, which use the heat of gases to produce electricity. All energy transformations involve losses, so the optimization of these equipment and systems will be crucial in the proposal of more efficient alternatives.

Steam turbine MAN MARC (© MAN)

The technologies considered in the project include new developments of electric motors aimed at increasing power density and efficiency, such as advanced induction motors or permanent magnet motors. Within this field, several application cases will evaluate the convenience of using “power-take-off” power generation systems, combined with “power-take-in” electric propulsion, in which the same machine thanks to the use of the power electronics, it can have dual operation.

Within this group of technologies will also be evaluated the systems of use of energy, both exhaust gases and cooling systems. The technologies will be based on steam turbine systems, absorption chillers and Organic Rankine Cycles.

- Propulsion

The energetic efficiency in the propulsion consists in finding the optimal system of transformation of the rotating mechanical energy of the motors, diesel or electric, in the advance of the ship. The project has considered different types of boats, and therefore, the propulsion systems range from the directly coupled propeller, to counter-rotating propellers, through azimuth systems. By means of the use of parameterizable models of different propellers in each case of application it will be possible to evaluate the overall efficiency improvement in the ship, with different propulsion alternatives.

- Post treatment of exhaust gases

During combustion, the contaminant components contained in the fuel pass to the exhaust gases, in the form of sulfur oxides, nitrogen oxides and solid particles in suspension. All these components are harmful to both health and the environment. Sulfur oxides produce acidification, nitrogen oxides eutrophication, and solid particles in the atmosphere cause lung cancer.

Currently, there are different techniques for the elimination of these pollutants from exhaust gases, starting from the use of cleaner alternative fuels, such as LNG or fuels with a very low percentage of sulfur, to the treatment of gases. The main systems used are the sulfur scrubbers known as scrubbers, the SCR (Selective Catalytic Reduction) that reduce nitrogen oxides, and the filters of solid particles in suspension.

Through the simulations, the reduction of emissions of these systems and their impact on the overall reduction throughout the life of the vessel will be calculated. In this evaluation, it is important not to forget that gas treatment systems involve additional consumption of other substances such as urea, and of course require maintenance.

- Storage and distribution of electricity

Marine system Seanergy 41MFe (© Saft)

Marine system Seanergy 41MFe (© Saft)

The storage, distribution and conversion of electricity from the point of production, usually diesel engines, to consumers, involves a transfer of energy and therefore losses. The optimization of this system therefore offers a great opportunity for energy savings. Specifically, electricity storage systems are especially interesting as long as there are operational profiles with power demands with a lot of variation in small time ranges. In these cases, the electricity storage system will allow the generators to work at more stable and efficient loads, storing energy during low demand, and contributing to peak demand. At the same time this system allows in many cases to reduce the size of the electric plant, maintaining the capacities of the ship.

By using models, electrical distribution and conversion architectures will be optimized, taking into account the most appropriate electrical storage capacity for the needs of each application case.

Models of electrical conversion components have been developed such as frequency converters, inverters, rectifiers, transformers, as well as models of different electricity storage systems, such as Li-ion batteries, flywheels, or ultracapacitors.

- Consumption on board

The different consumers on board will depend a lot on the type and function of the ship, although generally one of the main consumers is the air conditioning, heating and ventilation system (ACCV).

An integrated ACCV model with an energy consumption model of the cabins has been jointly developed. The cabin model includes models of systems and common equipment such as fans, coolers, heaters, and dehumidifiers. The union of the cabin model together with the ACCV will make it possible to assess the energy consumption and environmental control in an integrated manner.

- Renewables

Wind energy collector in marine propulsion systems (© TU Deflt)

Wind energy collector in marine propulsion systems (© TU Deflt)

Renewable energy sources are always an inexhaustible and clean alternative to consider. Although due to the low power density of current technologies can not be considered as primary producers to replace diesel engines, they can be used as complementary and clean source to reduce the demand for fossil fuel and therefore emissions.

The two main sources of renewable energy that are considered in the JOULES project are solar photovoltaic and wind energy. Regarding wind energy, one of the application cases will develop wind propulsion models for cargo ships with sails, in order to assess the future technical feasibility of this technology. It has also focused its attention on the development of practical and commercially viable wind propulsion systems for partial or total propulsion.

The Behavior Prediction Program at sea, developed by the Delft University of Technology, is already being analyzed in different shipyards that are evaluating different alternative configurations.

Simulation of the global energy model of the ship

All these technologies aimed at energy saving and emissions reduction in the maritime industry, have had in recent years an important advance, motivated mainly by the regulations promoted by the International Maritime Organization, IMO. But the individual analysis of the technologies does not allow a real assessment of the possible alternatives. If, instead of focusing on a particular component, the potential for improvement is extended considerably, to an overall energy model of the ship. For the realization of this kind of analysis, the traditional calculations made with Excel are no longer valid, since the increase in complexity makes it necessary to use advanced numerical simulation tools, which allow to compare the different systems in a reasonable way.

- Approach of energy efficiency alternatives

Once the technology manufacturers made the study of the state of the technology to provide the project with a sufficiently solid body of knowledge, the shipyards analyzed the possible alternatives for generation and consumption of energy (mainly propulsion) taking as a reference the configuration of our baseline vessels, together with its specific operational profile.

In order to evaluate the possible improvements obtained with the integration of new energy efficiency technologies at the system level, ship models for the reference ship have been made, and for the 2020, 2050 designs.

The results of these simulations are mainly oriented to the valuation of fuel consumption and emissions of polluting gases under the operating conditions established in each case of application.

Evaluation of behavior in the life cycle

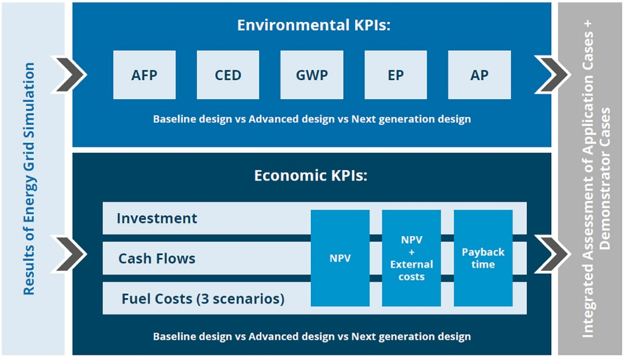

The results obtained in the simulations of the ship energy models have been used to perform a Life Cycle Behavior Assessment. The main indicators (KPIs) that have been taken into account in the tools are the following:

- Accumulated Energy Demand (CED), aimed at the depletion of resources.

- Global Warming Potential (GWP), aimed at climate change.

- Acidification potential (Acidification Potential, AP), aimed at damages such as, for example, acid rain.

- Potential for Eutrophication (Eutrophication Potential, EP), aimed at over-fertilization and sensitive marine areas.

- Potential of aerosol formation, (Aerolsol Formation Potential AFP: directed to damage to health due to particulate matter.

Integrated evaluation methodology

Integrated evaluation methodology

The main indicator that has been considered is the Global Warming Potential (GWP) of each technology. The GWP is defined as the combination of the effect of CO2 and methane emissions (CH4) taking into account the contribution on the indicator from the manufacture of fuel to its consumption, by means of the concepts, “from the well to the tank” (“well to tank “), or” from the well to propeller “(” well to propeller “). The climate impact is referred to a horizon of 100 years.

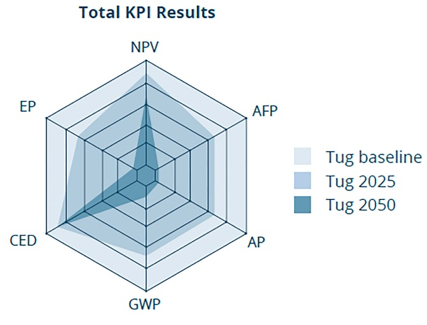

Comparison of KPIs for design alternatives

Finally, the Methodology of Economic Evaluation and Environmental Integration covers the environmental KPIs as a whole, and adds an additional indicator, the Net Present Value (NPV). The economic evaluation compares the different technological solutions implemented taking into account financial aspects, such as fuel costs, investment costs, extraction costs, etc.

Finally, both contributions are integrated into the “Life Cycle Performance Assessment” tool, LCPA, thus achieving a holistic evaluation methodology for each of the design configurations, for each application case. The results are compared by means of spider web diagrams, in which the minimization of the graphic area supposes a global improvement, although certain indicators may have worse characteristics, in the new configurations.

Summary of practical cases

11 practical cases have been developed and evaluated. In general, the proposed design alternatives are based on the optimization of power distribution with different configurations. The energy efficiency improvement options considered include hybrid propulsion, heat recovery, the use of fuel cells, the charging of batteries from port connections, the use of less polluting alternative fuels, and alternative energies.

Results of advanced designs (2025) and new generation designs (2050)

Results of advanced designs (2025) and new generation designs (2050)

- Case of application Navantia: Patrol Vessel

The base ship that has been taken as a design reference, is a medium-sized patrol boat. The propulsion system of this ship has two lines of axes, each powered by an electric motor and a diesel engine, both coupled to a reducer, which will allow them to work one or the other, but not both at the same time. The power plant consists of four diesel generators, with enough capacity to reach the maximum speed in electric mode and feed the ship’s consumers according to the electrical balance.

-

- Description of the means of energy efficiency in the concepts 2025 and 2050

In general, conceptual designs 2025 and 2050 will maintain the maximum similarities with the reference ship, so that the impact on consumption and emissions savings of the energy efficiency measures analyzed can be evaluated independently. The technological areas of optimization of energy efficiency that have been considered are the following:

- Improvement of hybrid propulsion solutions according to the particular operational profile, (more efficient diesel engines, configurations type PTI / PTO, “peak shaving”, etc …

- High density electrical machines

- Reduction of emissions in diesel engines (SCR)

- Electrical storage systems (lithium ion batteries)

- Connection systems and electric recharge to port

Model 2020 and 2050 for the application case Patrolman

Model 2020 and 2050 for the application case Patrolman

- Energy recovery systems (ORC)

- Alternative fuels (LNG)

- Reduction of electricity consumption (LED, CVAA system, pumps)

- Optimization of hydrodynamic operation through dynamic trim management system.

- Use of fuel cells

- Renewable energy for auxiliary generation (solar)

The results of the simulations of the models developed with these technologies, taking into account their different degrees of technological maturity in the 2025 and 2050 scenarios, yield a saving of around 20% in the GWP for the case of 2020, and more than 65 % for 2050

Experimental validation

Within the JOULES project, a series of demonstrators and tests have been carried out in order to gather information to validate the simulation models developed in the project.

The following table shows a summary of the trials carried out.

Conclusions and policy recommendations

In conclusion, the main results of the JOULES project are the following:

Use of models and intelligent simulations of energy management, based on standardized component models as a method to optimize energy efficiency in ships.

Establishment of potential technologies (state of the art and future implementation of innovative technologies) that facilitate the ambitious goal of short-term and long-term reduction of greenhouse gas emissions (GWP).

The large-scale reduction of GWP requires the acceptance and use of sustainable fuels that come from renewable energies. For this, the high costs and additional power required to obtain them should be compensated, in order to be able to compare them with conventional fuels.

The economic feasibility of technologies based on energy savings to reduce GWP emissions is not within the reach of current market conditions, so its implementation will require support in order to safeguard the sustainability of the environment.

As a result of this research work, the consortium of companies that form JOULES recommends applying the following policy measures in a sequential manner according to their respective urgency:

Guarantee future regulations through calendars and requirements.

In case new regulations are required, ensure that the levels of demand are preferably aligned with the IMO levels.

Provide a short-term program to enhance energy recovery systems.

Activities of R & D sponsors in order to improve the efficiency, useful life, costs, weight and required packaging of innovative technologies, such as fuel cells, energy storage systems and new concepts of electrical distribution.

Support intersectoral analysis systems to identify macroeconomically optimal solutions for future zero emissions concepts, combining new technologies together with sustainable fuels.

Provide long-term financial support to implement sustainable fuels from renewable energy with low emission levels and the integration of future innovative technologies in shipbuilding.

Scheme of transition towards future neutral costs with zero emissions

Article written by Gema Blanco Montes

Internal Communication Navantia Bulletin – N. 38 | June 2017