Smart Shipbuilding

The digital transformation driving efficiency and sustainability at Navantia.

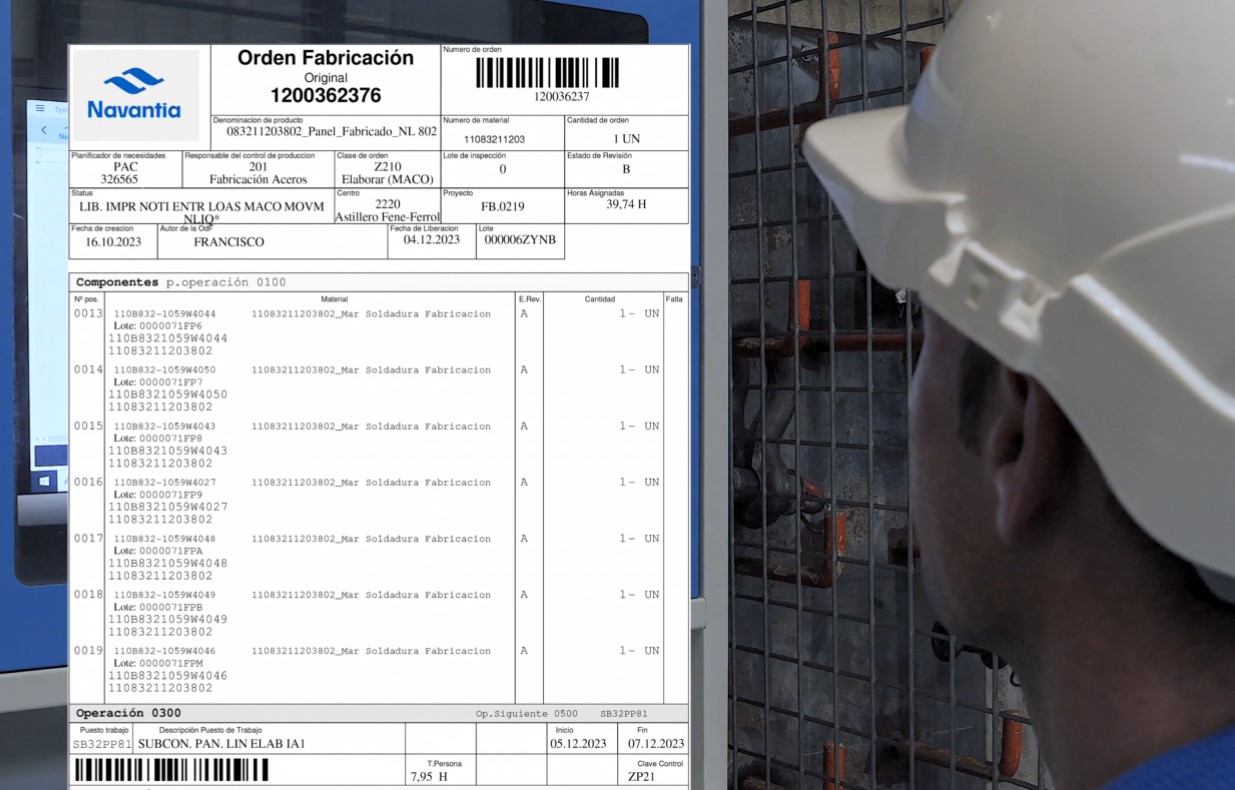

Automation and data for efficient production

industrial transformation

Technologies

Technology solutions

Advanced engineering innovation centre

End‑to‑end digitalisation of the naval environment

Innovation applied to continuous improvement

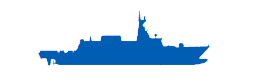

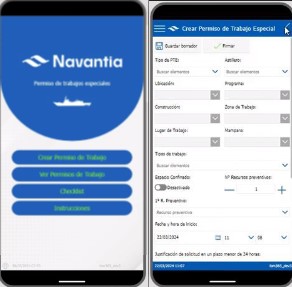

Navantia’s Smart Factory is a cyber‑physical environment that brings together all the digital capabilities needed to achieve operational excellence by designing and manufacturing products and services in a differentiated, efficient and sustainable way.

The Smart Factory achieves efficiency and sustainability through automation, robotics and digitalisation, continuously optimising processes with analytics‑ and AI‑driven simulation. It acts across the entire value chain, simplifying operations, reorganising resources and supporting decision‑making to adapt to a flexible environment without sacrificing efficiency. It is implemented through process re‑engineering, driving innovation with enabling technologies and transforming human capabilities to meet new challenges.

Flagship Programmes

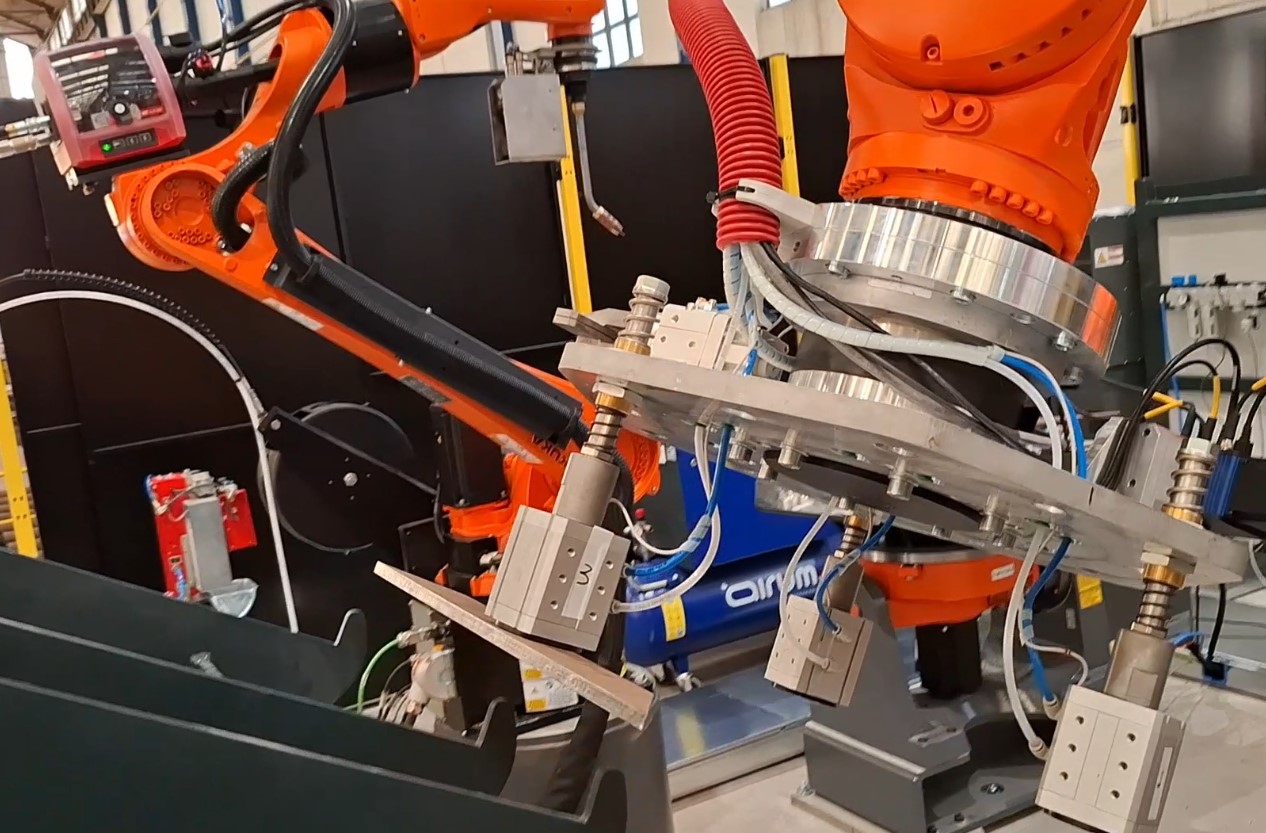

These flagship programmes are initiatives that deploy operational excellence across the board, reflecting the vision Navantia wants to bring to all its sites and processes. Navantia has defined four such programmes, which cover both the representative processes of ship construction at our shipyards and the vision for our factories. To support the high level of innovation these programmes require, the CIR (Innovation and Robotics Centre) has been created.

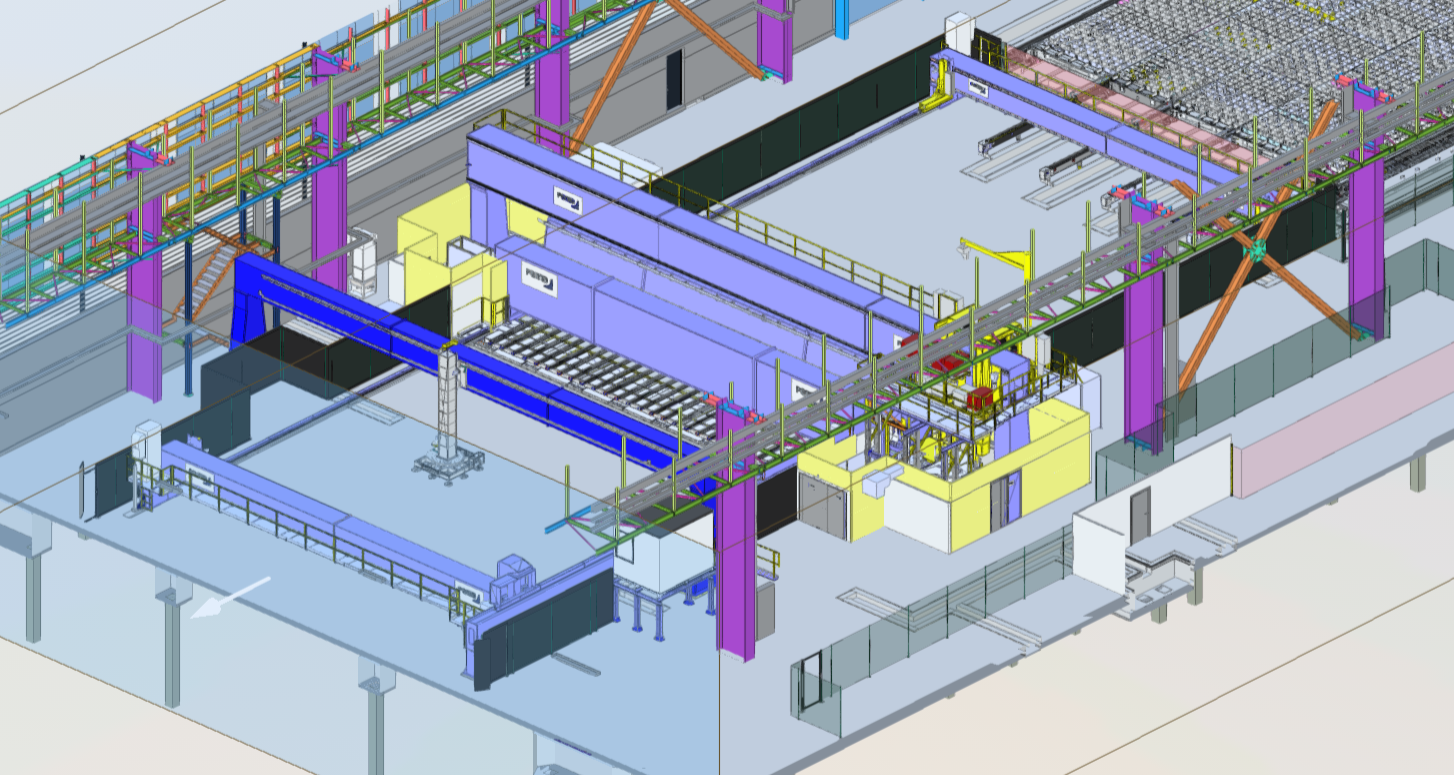

Ferrol Digital Block Factory (FdB)

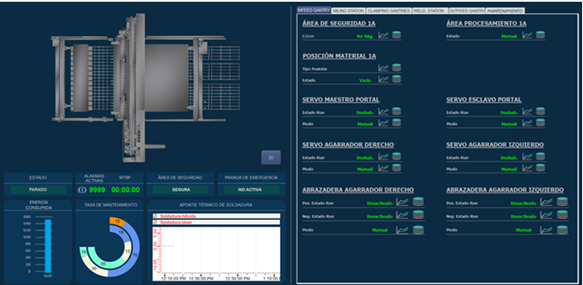

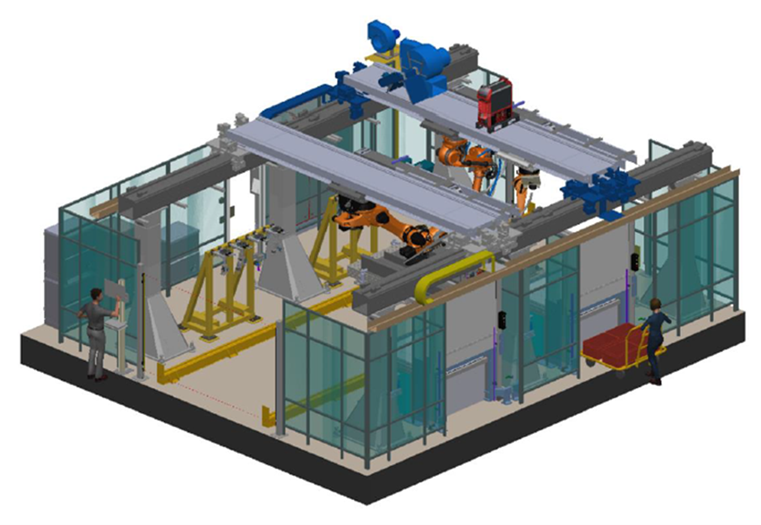

FdB is a flagship programme that covers the full process of preparation, steel processing, sub‑block and block formation and pre‑outfitting for the ships built at the Frigates and Intervention Vessels Business in Ferrol. It incorporates an automated line for manufacturing panels and open units, featuring robotics with hybrid laser welding, AGVs for internal movements and robotic cranes for transferring intermediate products. Designed using simulation tools, it lays the groundwork for a digital twin that will manage data from IT and OT networks and from a SCADA system. It also includes a robotic cell for pre‑assembled bulkheads and robots for weld inspection, dimensional control and painting, eliminating systematic pickling and enabling robotic surface treatment and inspection in clean environments.

Flat Open Units Workshop (TUAP) in San Fernando

TUAP is a fully automated workshop that includes a panel and open‑unit manufacturing line. This line is similar to the one installed at FdB and also features hybrid laser welding. Like FdB, the workshop has been designed using simulation tools, which will also underpin the configuration and deployment of the plant and process digital twin. This digital twin will execute tasks using process data gathered from the IT and OT networks and plant data accessed via a SCADA system.

Flat Panel Line (LPP) in Puerto Real

LPP is a fully automated workshop that includes a panel and open‑unit manufacturing line similar to that at FdB, with hybrid laser welding. Designed with simulation tools, it provides the foundations for a digital twin that will manage data from IT and OT networks and from a SCADA system. It is also ready to process steel for offshore substations.

Cartagena Engine Factory

The Engine Factory has incorporated digital management and control tools that cover digital planning and administration, automation and RPA. Analytics and AI have been deployed to manage load balancing, carry out root‑cause analysis and implement intelligent materials management.

Roadmap towards the Smart Factory

Navantia is advancing towards the Smart Factory through three perspectives and six lines of action. The enabling perspective lays the foundations for the deployment of digitalisation. It defines the IoT architecture, standardises digital tools and connects and integrates these solutions.

Navantia Innovation and Robotics Centre in Ferrol

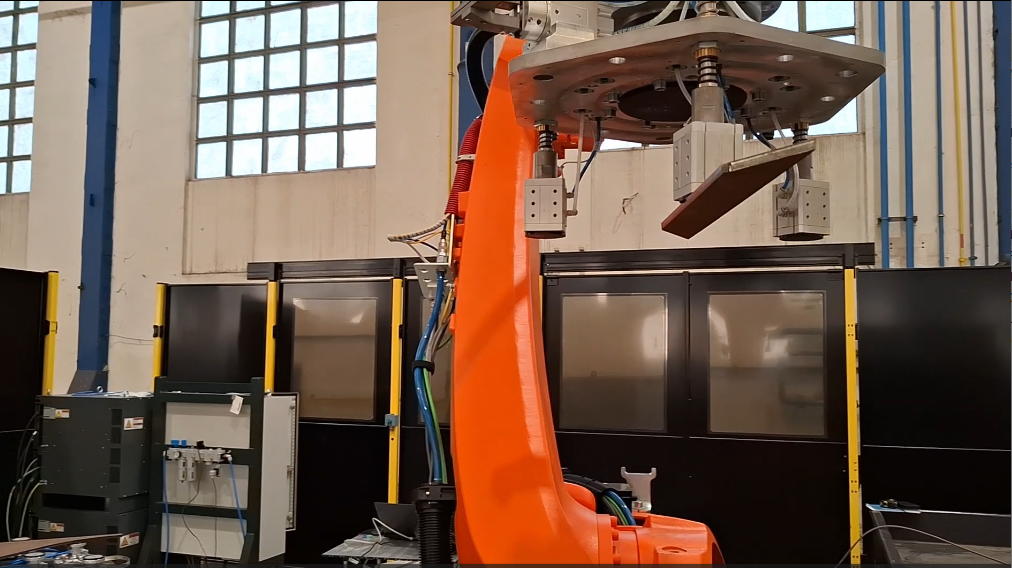

The CIR is an innovation centre whose main goal is to deploy and test digital solutions in a pre‑industrial environment before rolling them out to shipyards and factories. The CIR also designs, builds and validates robotic solutions, which require dedicated innovation projects ahead of industrial deployment.

Benefits of the Smart Factory

Navantia’s Smart Factory is fully aligned with the company’s strategic sustainability goals. Improving process and product quality directly reduces rework, which in turn lowers material and energy consumption and minimises waste generation. Process re‑engineering has also eliminated redundant activities – such as the shop‑priming process at FdB – with a direct impact on emissions, energy use and raw material consumption. The Smart Factory is the driving force behind standardised design solutions and manufacturing processes.

A revolution in the workplace

Automation makes it possible to move away from arduous or high‑exposure tasks, improving workers’ health, quality of life and productivity. The Smart Factory provides a platform for incorporating new specialist disciplines, promoting the technical upskilling of the workforce and ongoing improvement.

Health improvements

and better quality of life for workers

Higher productivity

driven by automation

More specialised work

and continuous improvement

Innovation projects

Driving technology through industrial innovation projects.