Capabilities

Tailored global solutions wherever needed

Tailored global solutions throughout the product lifecycle

Navantia supports its customers throughout the entire lifecycle of the ship or system, offering tailored solutions at every stage. Its broad portfolio of additional services (design/ToT, construction, systems development and integration, repair and lifecycle support) strengthens and expands industry‑customer relationships, establishing long‑term global solutions. Navantia also has proven engineering capabilities to design and integrate all types of equipment and systems on ships and other non‑naval units at its various sites. Navantia has all the capabilities required to provide each customer with a global solution adapted to their requirements and specific needs.

Navantia Capabilities

Navantia offers a wide range of additional services that complement its core activity, ensuring maximum added value.

Navantia Shipyards

Navantia can boast proven engineering capacity to design and integrate all kinds of equipment and systems for all types of ships and other non‑naval units, as well as extensive facilities and skilled personnel at its shipyards in Spain and the United Kingdom. It has all the capabilities required to provide each customer with a global solution tailored to their requirements and specific needs.

Ferrol Shipyard

The Ferrol shipyard builds the F‑110 frigates for the Spanish Navy and also offers ship repair and modernisation services. It integrates combat, propulsion, engine and turbine systems and provides full logistics support, ensuring efficient, high‑tech naval lifecycle solutions. With one hundred years of history, Ferrol has already embraced Shipyard 4.0 and process digitalisation. Its repair centre and systems workshops ensure critical maintenance and upgrades, while its engine and turbine lines strengthen fleets’ operational autonomy.

San Fernando Shipyard

The San Fernando shipyard leads the construction of AVANTE 2200 corvettes with hybrid laser technology. It offers extensive ship repair and modernisation services, integrates advanced naval systems and collaborates on green energy projects, providing comprehensive lifecycle solutions for maritime assets in a strategic way. Since its founding, San Fernando has integrated digitalisation and virtual twin processes. It has naval systems facilities and a service centre for comprehensive maintenance and modernisation. It participates in marine energy and propulsion projects, reinforcing its commitment to sustainability, industrial competitiveness and continuous technological development.

Puerto Real Shipyard

The Puerto Real shipyard is Navantia’s largest site, home to the biggest flat panel workshop in Europe, capable of producing panels up to 20 by 22 metres and weighing up to 150 tonnes.

In recent years, these facilities have specialised in offshore structures for offshore wind energy, manufacturing jackets, fixed and floating structures, and integrated solutions for electrical substations. With its capacity for large‑scale projects, Puerto Real has become a key hub for the energy transition and the decarbonisation of the maritime and energy sectors.

Cartagena Shipyard

The Cartagena shipyard is a benchmark in the construction and maintenance of submarines, including the S‑80 Plus programme. It has specialised facilities for integrating combat systems, leak testing and validating complex systems. Together with its engine centre, it promotes technological solutions for advanced naval propulsion and energy efficiency. Cartagena combines tradition and innovation, strengthening Spain’s strategic autonomy in submarine defence.

Fene Shipyard

The Fene shipyard, in the Ferrol estuary, has become a reference hub for offshore wind and offshore structures. Specialised in fixed and floating foundations for wind farms, it delivers turnkey solutions for major energy developers. Fene also participates in naval programmes and innovative prototype structures, combining heavy construction capabilities, advanced engineering and sustainability. Its activity drives skilled employment and industrial development in the region through Navantia Seanergies COEX Green Energies.

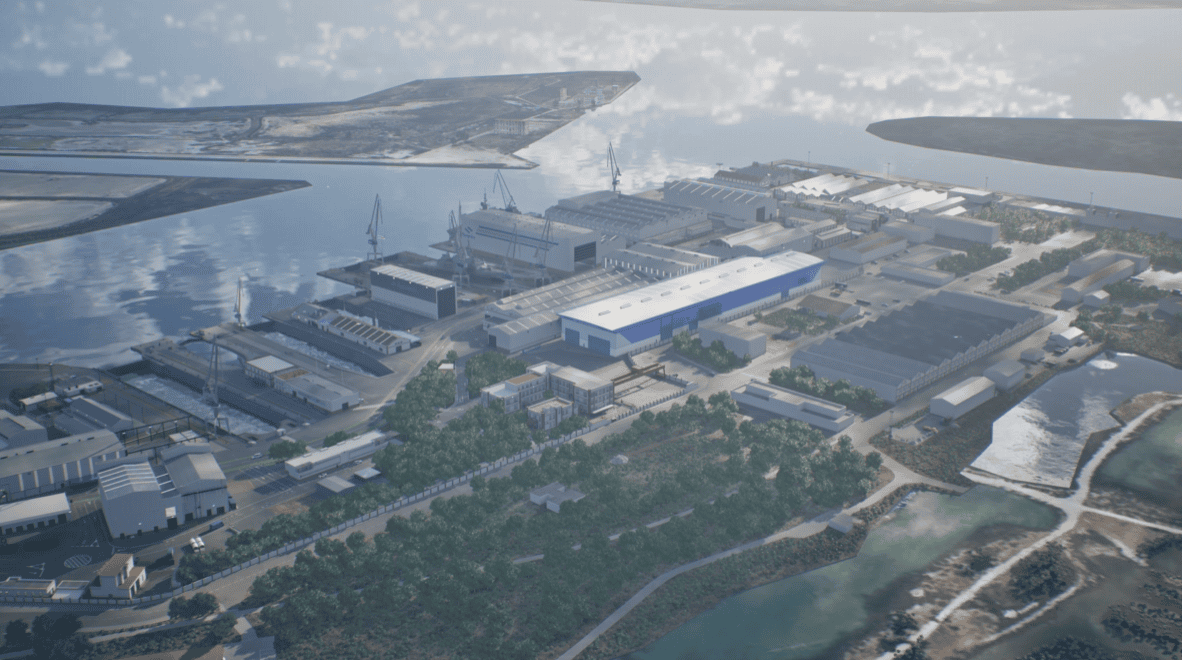

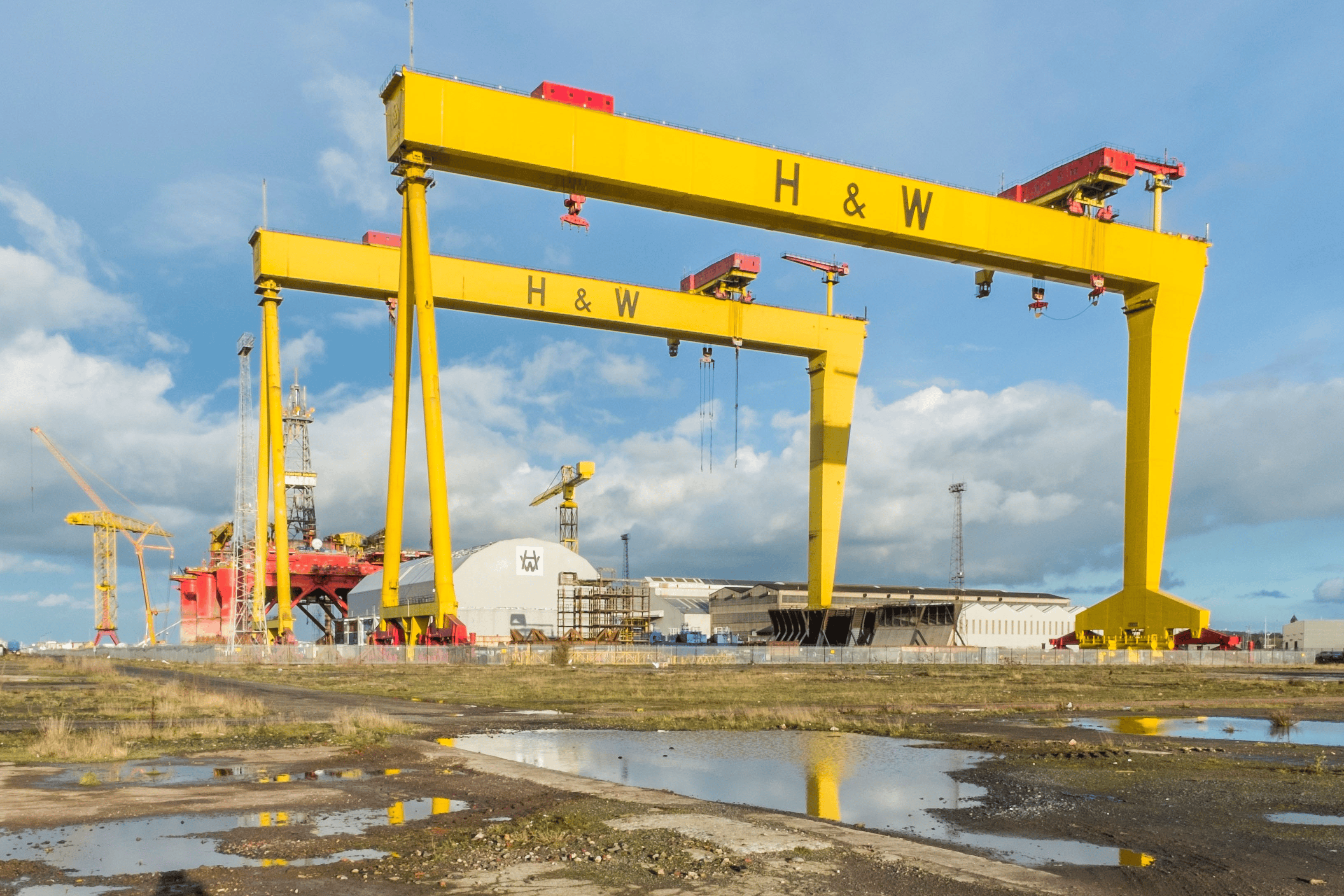

Belfast Shipyard

In Belfast, Navantia UK is revitalising the historic Harland & Wolff shipyards, delivering construction of logistics support vessels and specialised repair services. It integrates combat systems, propulsion and modernisation services. It collaborates with the Royal Navy and participates in marine energy projects, strengthening a sustainable naval industry in the UK.

Flagship Programmes

The flagship programmes are initiatives that deploy operational excellence globally, reflecting the vision Navantia aims to bring to all its workplaces and processes. Navantia has defined four flagship programmes. These flagship programmes cover both the core processes of shipbuilding at the shipyards and the vision for the factories. In addition, to support the strong innovation drive required by these flagship programmes, the CIR (Innovation and Robotics Centre) has been created.