Last Friday, Navantia Seanergies commissioned its first project for an offshore wind farm in the United States (USA). These are two modules for connecting the substation to its base, made in Puerto Real (Cádiz, Spain) for a wind farm on the east coast of the United States, a country that offers great opportunities for the offshore wind industry. The modules left the Puerto Real shipyard last Sunday 25th.

The structures commissioned to the client, one of the international leaders in offshore wind power, are complex pieces with high quality and reliability requirements, since they make the connection between the substation superstructure module and the monopile foundation. Both structures have been strongly protected against marine corrosion thanks to a sophisticated and delicate coating of their entire surface by direct spraying of molten metal, a zinc and aluminium alloy, Thermal Spray Zinc Aluminium (TSZA). This innovative procedure, which guarantees the protection of these structures against corrosion in a marine environment throughout their life cycle, has never before been applied to such a large surface area as these structures.

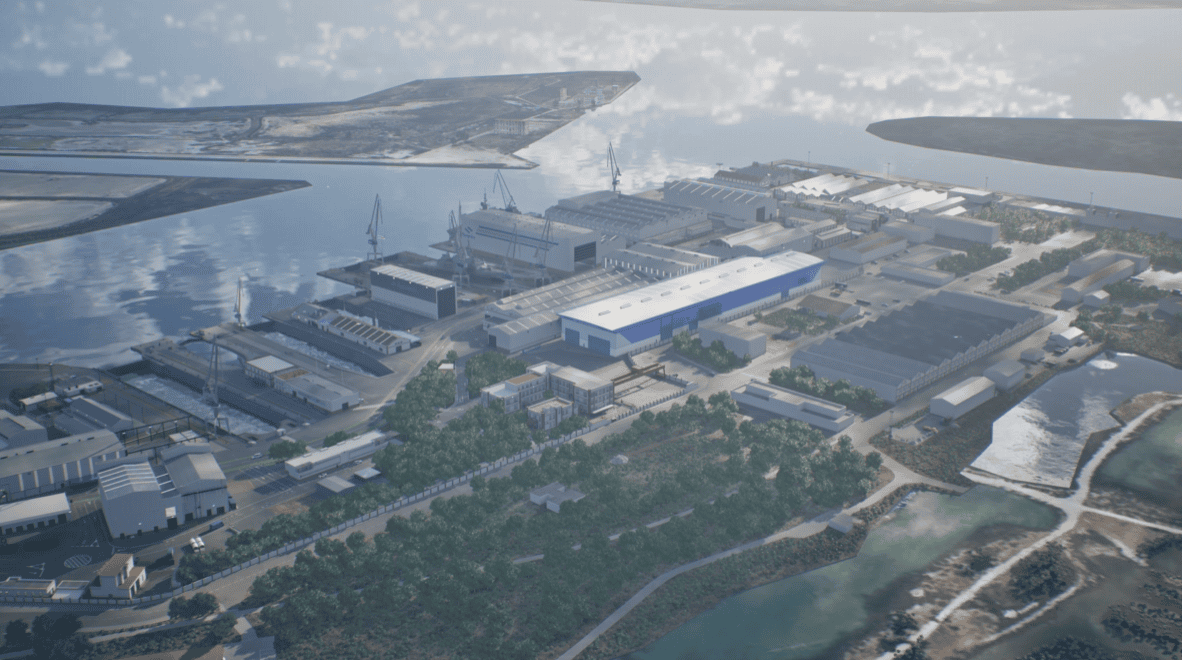

The detailed engineering, the purchase of materials and the construction were carried out at the Navantia’s Puerto Real Shipyard.

“With this commisioning, Navantia Seanergies consolidates its position as a supplier beyond the European continent. Navantia is firmly committed to the future potential of all its sites and is investing heavily in strengthening its facilities. We are carrying out intense bidding activity for the United States, and we hope to be able to confirm new orders soon,” said Navantia Seanergies director Javier Herrador.

The United States’ offshore wind farm development plans are very ambitious. In March 2021, the country set the goal of having 30 GW of fixed offshore wind energy capacity by 2030, with the possibility of reaching 110 GW or more by 2050. In floating technology, the goal is to reach 15 GW of capacity by 2035.

As part of its determined commitment to optimise the competitiveness of all its centres, the Navantia shipyard in Puerto Real has made significant investments that will boost offshore wind power, highlighting the installation in the Flat Block Workshop of a new, fully automated flat panel manufacturing line that will be the largest in the world.

These pieces have required a workload of more than 200,000 hours and some 200 direct jobs for the Puerto Real shipyard.

The loading out manoeuvre of the two modules in Puerto Real began on 19 August. The shipyard loaded the pieces, whose size and weight require complex logistics and work on the same transport vessel to secure the structures that will travel across the Atlantic Ocean for several weeks.

Two substation jacket projects are currently under construction at the Puerto Real shipyard, one for the Norwegian builder Aibel and another for Ocean Winds. The latter developer also signed a capacity reservation agreement for offshore wind elements with Navantia Seanergies. In addition, several substation projects are in the advanced commercial phase, which combined will generate between 600-800 jobs and activity until 2032.

For its part, the Fene shipyard is immersed in the construction project of 62 large jackets for the French offshore wind farm Le Treport, as well as several monopile projects for fields in the United Kingdom, Germany and Poland.