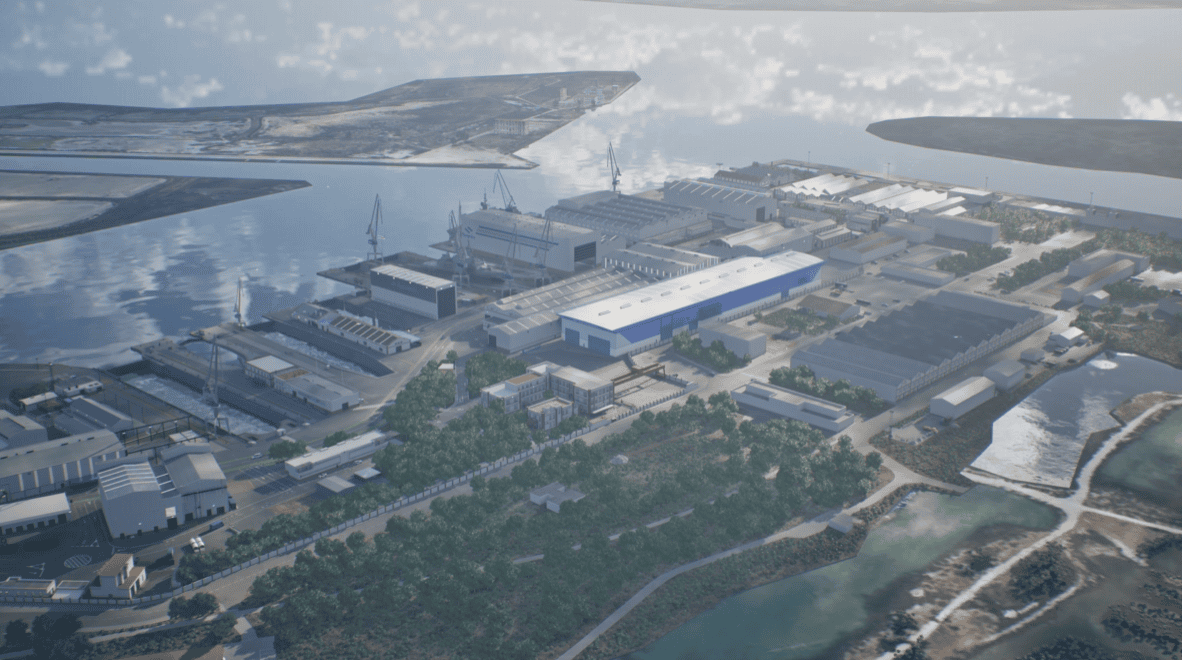

Navantia shipyard in Ferrol (A Coruña) has hosted this Wednesday the keel laying ceremony of the F111 frigate, whose construction began in April 2022 and which is the first of the series of five new generation frigates destined for the Navy.

This milestone in the programme took place in the presence of the Navy’s Chief of Staff, Antonio Piñeiro, accompanied by the president of Navantia, Ricardo Domínguez, and the director of the Frigates and Intervention Vessels business, Eduardo Dobarro.

The event consisted of the laying of the block 311 on which the rest of the ship will be built in slipway 2 of the Ferrol facilities. With this important event, Navantia continues to make progress in the construction of the five frigates of this series.

This ship is scheduled to be launched in 2025 and delivered to the Navy in 2028. The delivery of the remaining ships will be on a 12-month cadence until 2032, when the Navy will receive the fifth unit.

The F110 programme is well into its construction phase, with production ahead of schedule. To date, 18 of the 33 blocks that will make up the new F111 are in the manufacturing process, with a degree of maturity of the 3D model of the detailed engineering of around 80% and 99% of the platform equipment for all the ships in the series having been acquired.

Navantia has activated an acceleration plan for the construction programme, which was launched by fine-tuning the production systems with a pilot block, and which has materialised in this keel laying. Production of the F112 will begin before the end of the year.

«The F-110 programme is a vital project for the Navy, which will result in the necessary replacement of the «Santa María» class frigates, while complementing the capacity of our F-100s as basic elements for the development of the rest of the Fleet’s capabilities,» said Admiral Piñeiro. «This transition has been possible thanks to the excellent collaborative relationship between the Navy and Navantia, which has endured through decades of working together in a common interest in the pursuit of excellence in shipbuilding.

«The F110 is a transformational lever for our entire industrial and technological ecosystem. If this Ferrol shipyard is already a world reference in frigate construction, this programme will place it at the technological and industrial forefront, with the upcoming construction of the digital block factory and the Centre of Excellence of the Digital Twin», stressed the president of Navantia, Ricardo Domínguez.

The F110 programme will support around 9,000 jobs over a period of 10 years, taking into account both direct and indirect employment and that induced by economic activity. Around 500 companies from all over Spain are participating in the programme.

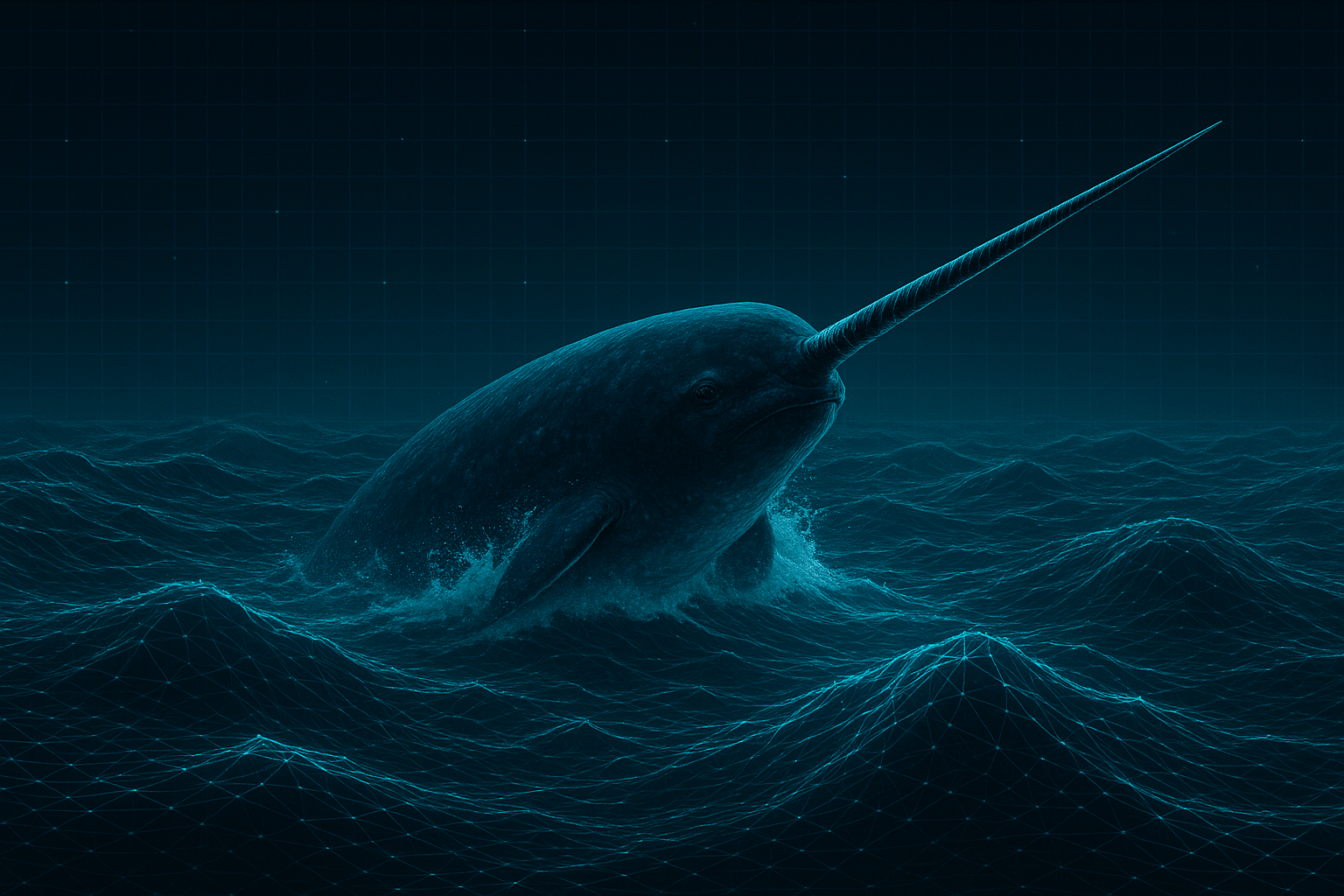

Five ships plus a digital twin

The F110 frigate programme, whose order of execution was signed in 2019, contemplates the construction of five units for a value of 4,325 million euros. These are multi-purpose escort vessels, with anti-aircraft, anti-surface and anti-submarine capabilities, and can operate in combination with other units. They are versatile vessels that can also perform functions related to maritime security and support for civilian authorities.

The F110 is a qualitative leap from the point of view of the Navy’s capabilities and the industrial and technological potential of Navantia and all its collaborating industry. It thus contributes to Spain’s strategic autonomy and to having a cutting-edge industrial and technological base, while at the same time opening up new export opportunities.

The programme incorporates the Digital Twin, an innovative concept that will make the Ferrol shipyard an international reference in frigates. The Digital Twin, designed in close collaboration with the Navy and the Directorate General of Armament and Material (DGAM) of the Ministry of Defence, is a virtual replica of the ship that is fed back in real time with information from the vessel and data permanently supplied by a network of sensors distributed throughout the ship, constituting a cyber-physical system that through the use of behavioural models and technologies such as Cloud Computing, Machine Learning or the Internet of Things (IoT) allows supporting its maintenance and operation even thousands of miles away through the Digital Twin deployed on land.