Welcome to Navantia

Naval construction, systems, repairs, services and Navantia Seanergies

Digital Product Portfolio

Product Portfolio

An innovative portfolio showcasing a selection of our key products, capabilities, and technologies

High value-added products and services

Navantia COEX Centres

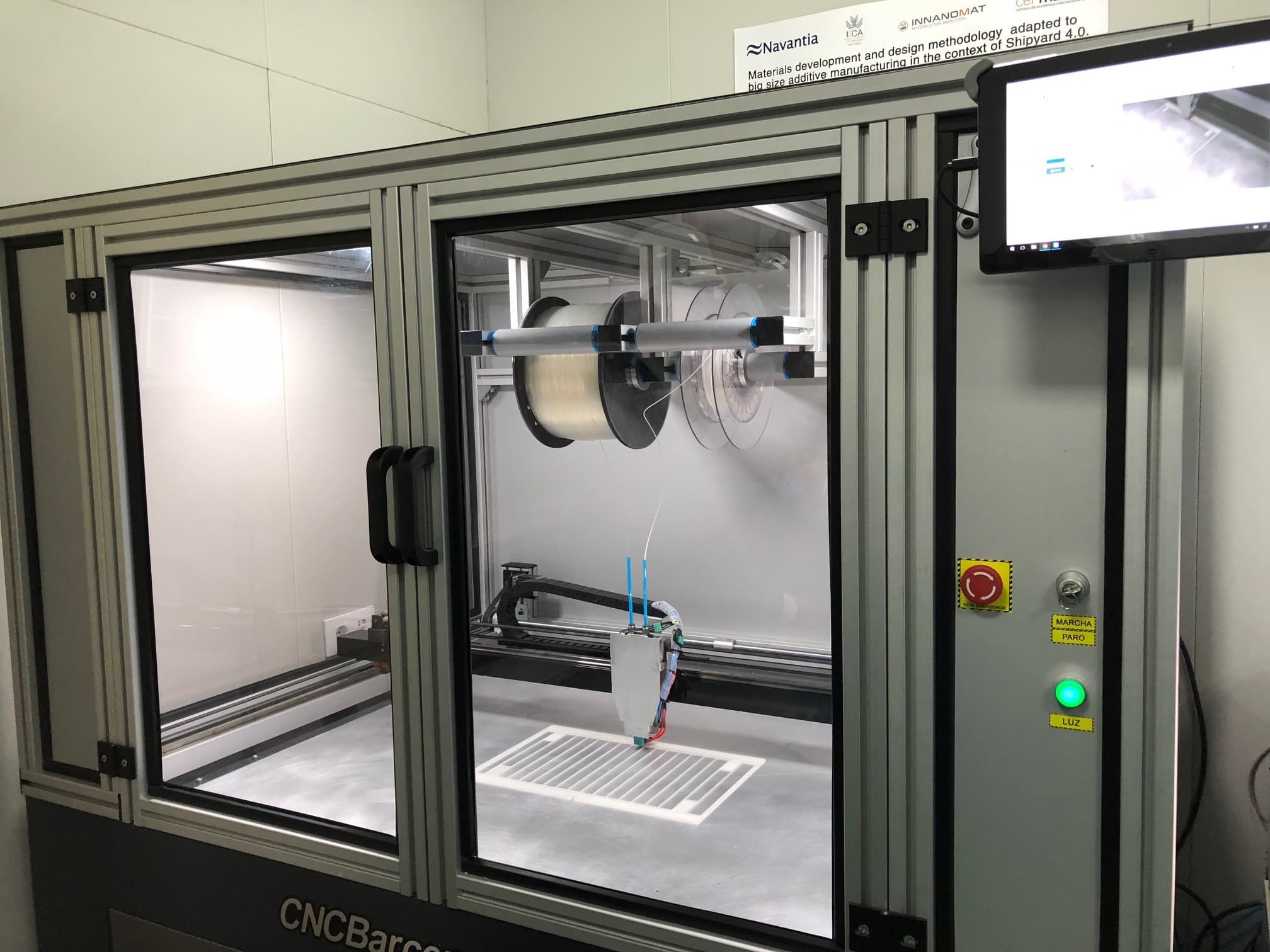

Navantia COEX · Advanced Manufacturing

materials manufacturing innovation

Navantia COEX · Digital

Twin

digital twins for optimal decisions

Navantia Seanergies COEX · Green Energies

marine energies, hydrogen and sustainability

Navantia COEX · Naval

Systems

cybersecure technology for advanced ships

Navantia COEX · Smart Services

smart services for reliable assets

Navantia COEX · Smart

Ships

innovative designs for future ships

Navantia World

Navantia Seanergies

Our green division: foundations, substations and floating offshore wind platforms

Navantia UK

Leading provider of advanced naval solutions. Discover our projects, innovations and leadership in the UK naval industry.

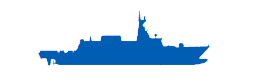

Navantia Australia

Navantia Australia is committed to supporting the growth of Australia’s shipbuilding and maintenance industry.